Products

-

Automatic pressure leveling and clearing ink machine

Technical Features

Adopt PLC control, flexible and reliable control mode

Two groups of pressing rollers, one or two groups can be selected to work at the same time

Flattening effect suitable for different requirements

Automatic detection of broken film

Using man-machine interface, easy to operate

-

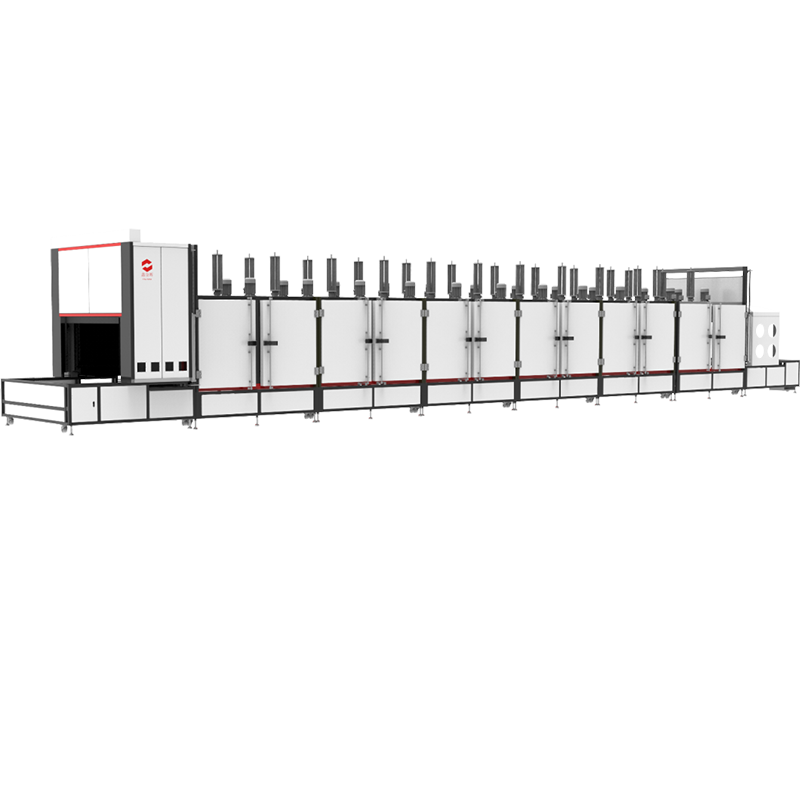

Frame type convery tunnel oven

PCB, BGA, FPC, COF, Display, Touch Panel, Back Light, Solar Cell, Smart Card, Optical Film, Battery and Semiconductor industries.

-

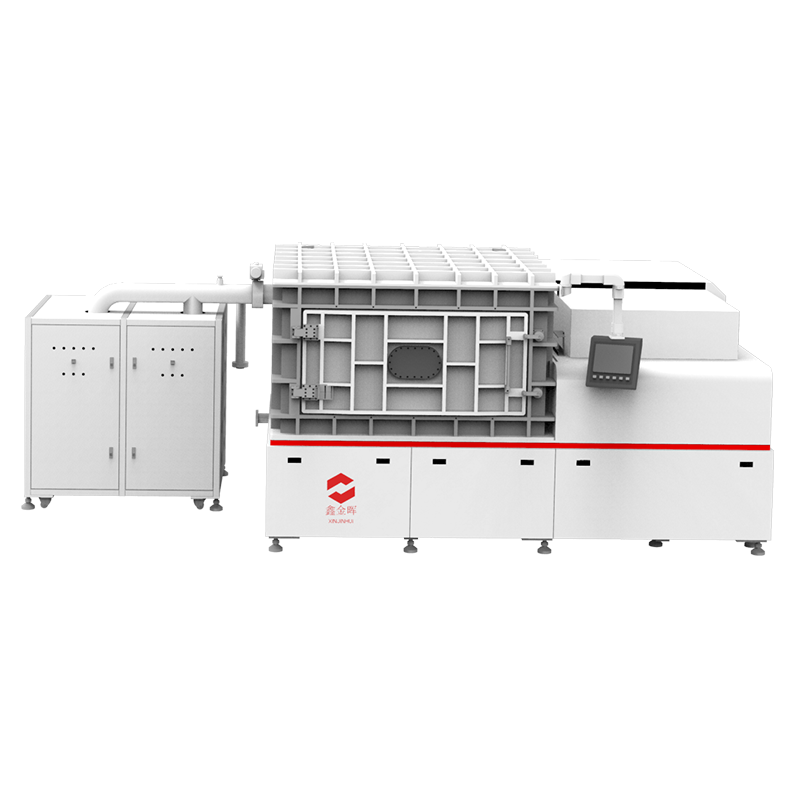

intelligent cacuum plug machine

The whole machine is composed of by the intelligent CCD system couterpoint, with its own vacuum system plug hole segment, it is suitable for high viscosity resin plug hole, the use of domestic and foreign well-known electrical hardware configuration, equipped with advanced design concept and stable mechanical structure ratio, and a number of patent technology support.

-

U Type IR Tunnel Oven/drying oven

Product Description

Industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed

travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is composed of feeding section, drying zone matching patented energy-saving generating system, air conveying system, heat preservation system, and unloading section. It adopts imported patented U-shaped conveying design, stable operation and good energy-saving effect. Suitable for pre-bake/post-bake circuit boards. -

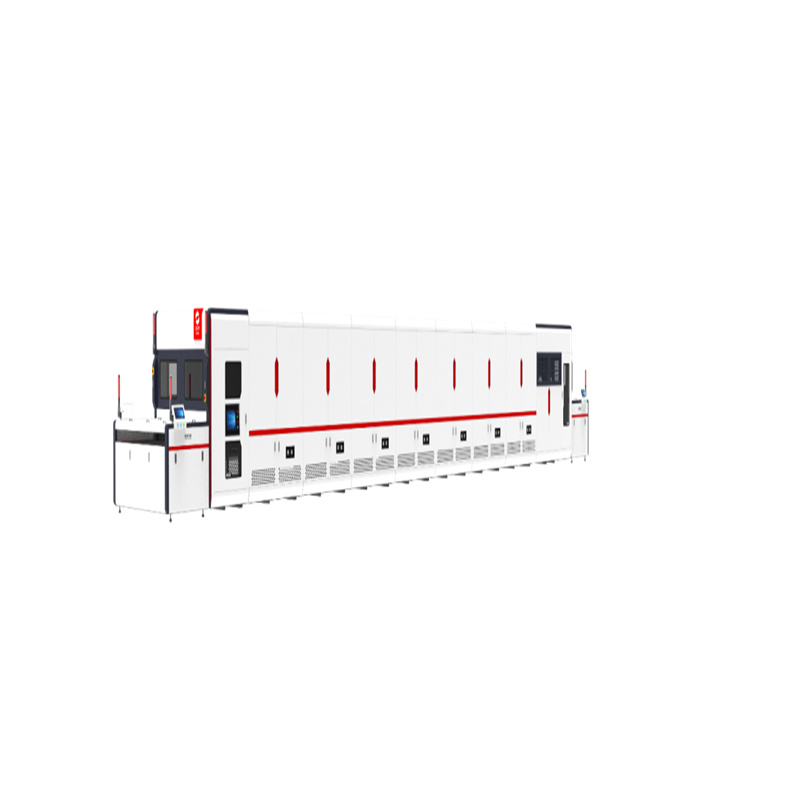

Double-Tunnel Page Turning Conveyor Oven

Product Description

Industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed

travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is composed of automatic diverter feeding, drying zone matching patented energy-saving heating system, air conveying system, heat preservation system, and automatic converging machine unloading composition. It adopts unique plate frame design, stable operation and good energy-saving effect. It is suitable for back of circuit boards bake. -

Overhang tunnel drying oven/// hanging type conveyor oven

Product Description

industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed

travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is composed of automatic feeding by a manipulator, the drying area is matched with a patented energy-saving heating system, an air conveying system, a heat preservation system, and an automatic feeding by the manipulator. Using unique patented suspension clamps, stable operation and good energy-saving effect. Suitable for pre-bake/post-bake circuit boards. -

Auto Lifting Buffer

product description

The whole machine is composed of loading section, lifting flap and unloading section. Using patented 18mm plate rack and chain conveyor design, stable operation. It is suitable for circuit board turning, cooling and temporary storage. -

Double Table Screen Printing Machine

Product Description

The whole machine is composed of double tables, suitable for circuit/solder mask/plug hole ink printing production process, adopts well-known electrical hardware configuration at home and abroad, equipped with advanced design concepts and stable mechanical structure ratios, and is supported by a number of patented technologies Ensure stable and reliable production and operation of products. -

Double -Door Vertical Hot Air Oven

Product Description

The drying area of the whole machine is matched with patented energy-saving heat system, wind system and heat preservation system. Good energy saving effect. Suitable for pre-bake/post-bake circuit boards. -

Semi-auto Screen Printing Machine

Product Description

The whole machine is suitable for circuit/soldering ink printing production process. It adopts well-known electrical hardware configuration at home and abroad, is equipped with advanced design concepts and stable mechanical structure ratios, and is supported by a number of patented technologies to ensure stable and reliable product production and operation. -

Independent double door vertical drying oven

Product Description

The drying area of the whole machine is matched with a patented energy-saving generating system, air conveying system, and thermal insulation system. Good energy saving effect. Suitable for pre-bake/post-bake circuit boards. -

Mesh type IR conveyor tunnel oven

Product Description

Industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed

travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is composed of feeding section, drying zone matching patented energy-saving generating system, air conveying system, heat preservation system, and unloading section. Adopting imported Teflon mesh belt conveyor design, stable operation and good energy-saving effect. Suitable for pre-roasting circuit boards.