Products

-

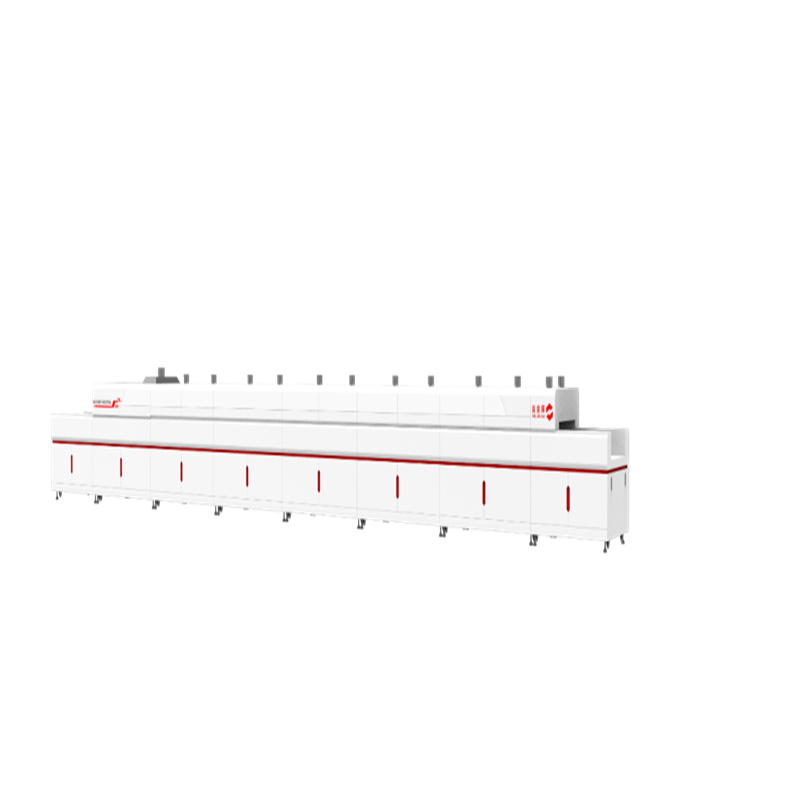

Roller type conveyor tunnel drying oven

Product Description

Industry conveyorised hot air tunnel ovens contain multiple individually electric heated zones, which can be individually controlled for temperature. For example ,PCBs being processed

travel through the oven and through each zone at a controlled rate with reel rolling transmission. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is composed of feeding section, drying zone matching patented energy-saving generating system, air conveying system, heat preservation system, and unloading section. It adopts imported patented roller conveying design, stable operation and good energy-saving effect. Suitable for pre-bake/post-bake circuit boards. -

Encapsulated tunnel conveyor drying oven

Product Description

Industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature.Packaging material being processed travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the Packaging material being processed at the time.

The whole machine is composed of feeding section, drying zone matching patented energy-saving generating system, air conveying system temperature system, and unloading section. Adopting a unique metal stall conveying design, stable operation and good energy-saving effect. Suitable for pre-bake/post-bake package substrates. -

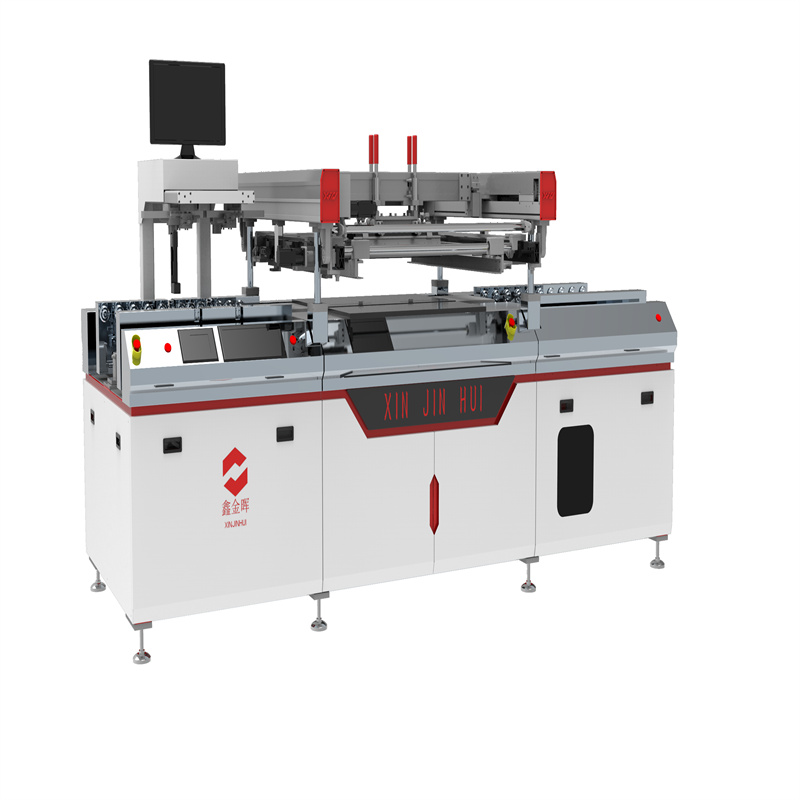

Automatic smart silk screen printing machine

1,Servo motor drives printing and pneumatic off screen to realize synchronous off screen function and effectively prevent screen sticking. The servo motor drives the printing piece to move quickly and smoothly to ensure the accurate positioning of the printing piece.

2,Servo motor and precision guide rail guide ensure accurate positioning and longer service life. The vertical horizontal lifting structure of the printing frame ensures that the pressure of the scraper is balanced.

3,smart interface touch operation, easy to set, and automatic fault detection and troubleshooting display. The printing pressure and screen plate can be adjusted conveniently and accurately, and the angle of the scraper can be adjusted at will.

4,CCD image automatic alignment system, combined with left and right running platforms, enables faster operation and high alignment accuracy. The multi value processing of the image system is not limited by any graphics, and any graphics can be used as a target.

-

Semi-Automatic Pressure Plug Machine

The whole machine has its own booster system plug hole section, which is suitable for high viscosity ink/resin plug hole. It adopts well-known electrical hardware configuration , is equipped with advanced design concepts and stable mechanical structure ratio, and is supported by a number of patented technologies. Ensure stable and reliable production and operation of products.

-

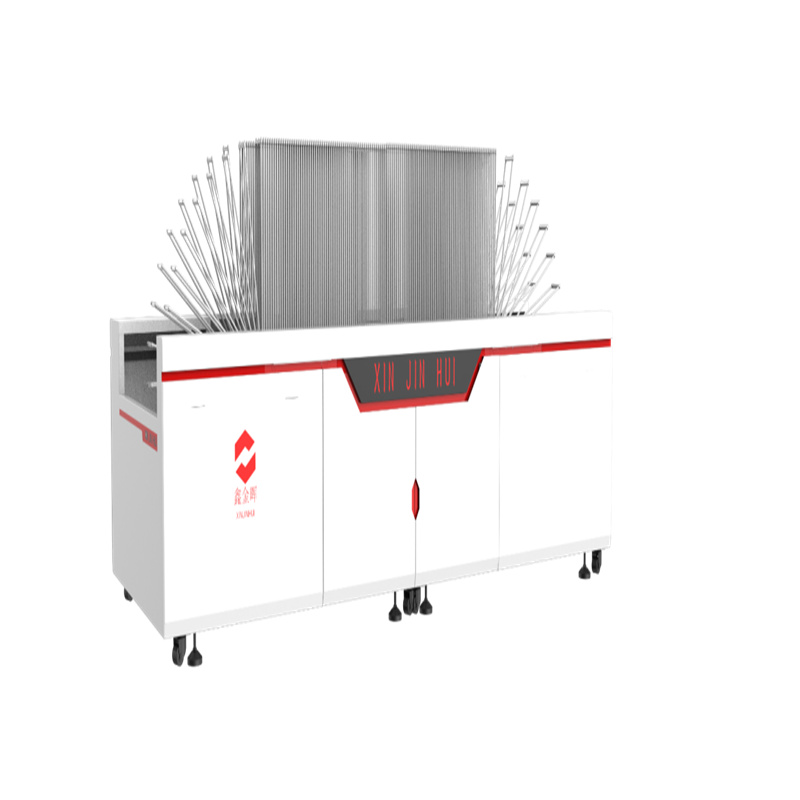

solar Profile Panel Turnover Buffer

Product Description

The whole machine is composed of a loading section, a sun-type flap, and a discharging section. Adopting patented ring-shaped disc conveying design, stable operation. It is suitable for circuit board turning, cooling and temporary storage. -

Page-turning horizontal transfer register

Product Description

The whole machine is composed of loading section, temporary storage rack and unloading section. Adopting patent circulation patent plate rack conveying design, stable operation. Suitable for temporary storage of circuit boards. -

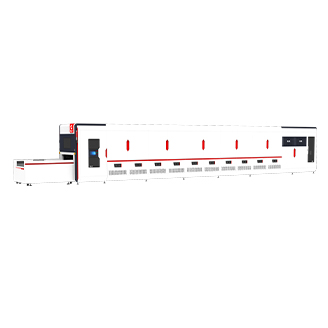

Side Clip Conveyor Tunnel Oven

Product Description

Industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed

travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is loaded by an automatic positioning platform, and the drying area is matched with a patented energy-saving heating system, an air transport system, a heat preservation system, and automatic feeding. It adopts a unique patented side-holding clip, stable operation and good energy-saving effect. It is suitable for pre-baking circuit boards. /After roasting. -

Intelligent Pressure Plug-via Screen Printer

Product Description

The whole machine is composed of a fully intelligent CCD system alignment section,

a plugging section with a booster system, and a material retreating section. The left

and right shuttle table moves the printed parts in series in the middle. Can meet high

viscosity ink/resin plug hole. -

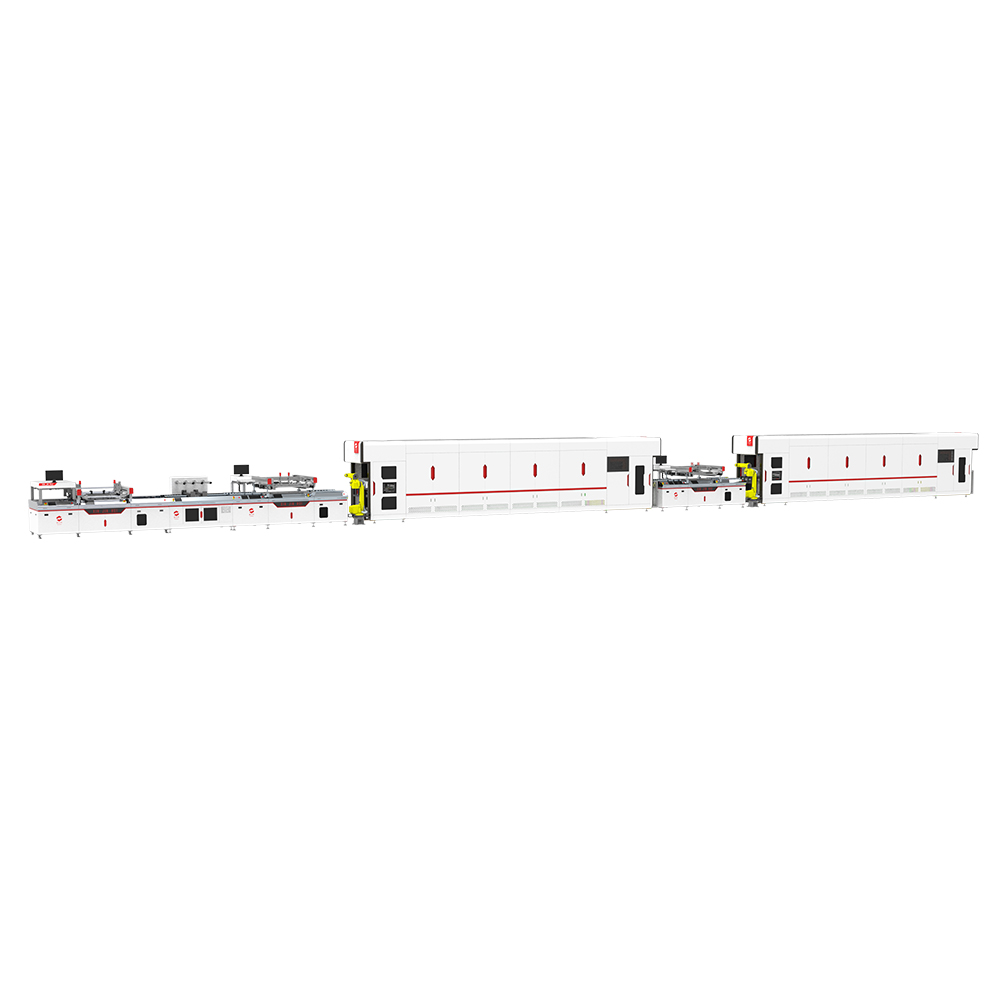

Fully Automatic Solder Mask Three Machine Continue Printing Line

Product introduce:Equipment configuration of the production line: intelligent pressure plugging-via machine → automatic leveling machine →A intelligent solder mask screen printer → automatic positioning turn over →B intelligent solder mask screen printer → side clip conveyor turnnel oven.

Full automatic plugging-via solder mask printing line: it is applicable to the PCB solder mask screen printing production process of multilayer panel, thin / thick circuit boards. It adopts well-known electrical hardware configuration, carries advanced design concepts, stable mechanical structure , and is supported by a number of patented technologies. Ensure stable and reliable production and operation of products. -

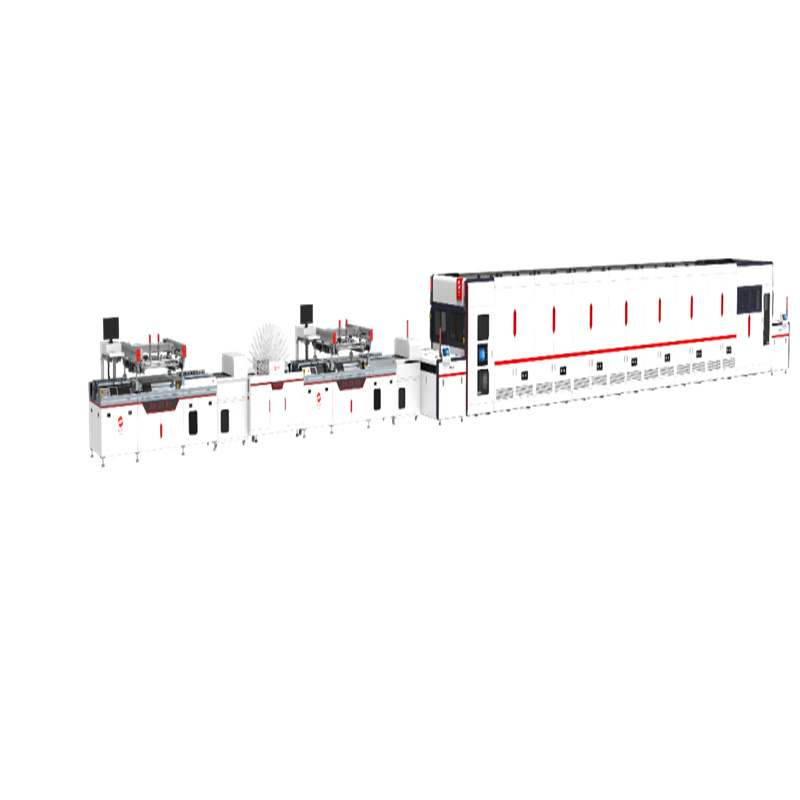

Fully Automatic Thin Sheets Solder Mask Printing Line

Product introduce: Equipment configuration of the production line: intelligent pressure plugging-via machine → automatic leveling machine →A intelligent solder mask screen printer → suspended conveyor oven →B intelligent solder mask screen printer → suspended conveyor oven

Full automatic thin plate solder mask production line: it is applicable to the solder mask ink printing production process of multiple material numbers, thin / thick circuit boards. It adopts well-known electrical hardware configuration at home and abroad, carries advanced design concepts, stable mechanical structure , and is supported by a number of patented technologies. Ensure stable and reliable production and operation of products. -

Fully Automatic PCB Legends Screen Printing Line

Product introduce: Equipment configuration of the production line: A intelligent screen printing machine → uv machine →Sun shape flipping machine → B intelligent screen printer → wicket conveyor turnnel oven.This machine is formed by connecting multiple machines to achieve fully automatic production efficiency;,it not only reduces the cost of manpower, but also it achieves the goal of energy saving and carbon reduction (from the original two-pass printing and baking twice to two-pass printing and one baking).

Full automatic PCB legends screen printing line: it is applicable to the PCB legends screen printing production process of multilayer panel, thin / thick circuit boards. It adopts well-known electrical hardware configuration, carries advanced design concepts, stable mechanical structure , and is supported by a number of patented technologies. Ensure stable and reliable production and operation of products.