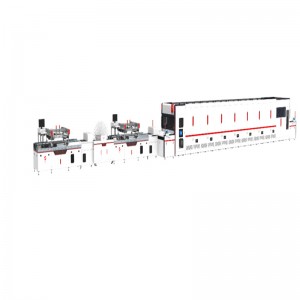

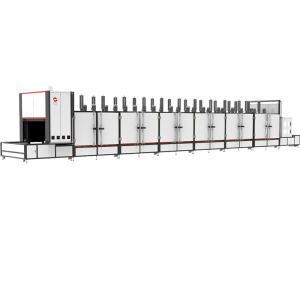

Double Table Screen Printing Machine

Using servo scraper bottom, frequency can be set and adjusted

The self-locking function is set mechanically to ensure the stability and balance of the plug hole silk screen

Fully intelligent alignment system, no need to adjust alignment by handwheel

Four-column power lifting system, with high mechanical strength, good rigidity and strong stability

PLC: MITSUBISHI

Rail: THK

Cylinder: AirTAC

Communication: MITSUBISHI

Touch screen: weinview

Synchronous belt: MEGADYNE

Bearing: NSK

Ball screw: TBI

Maximum processing size: 630 mm×730mm

Squeegee pressure uniformity: ≤5kgf

Minimum processing size: 350mm×400mm

Printing pitch: 0~10 mm

Board thickness range: 0.8-4.0mm

Clearance from the board: 0~10mm

Printing speed: 30~300 mm/sec adjustable

Fine adjustment of screen frame: X, Y, θ±5mm

Maximum screen frame size: 1200×1100mm

Fixed screen frame: fixed at six points

Minimum screen frame size: 800×800mm

Covering/scraping angle: ±15°

The smallest plug hole diameter: ≤ 0.20mm

Scratch stroke: servo 0~900 mm adjustable

Table top level accuracy: ±0.1mm/m2

Equipment power: 3 KWH

Plug hole accuracy: ±0.02mm

Equipment size: 1500×1700×1900 mm