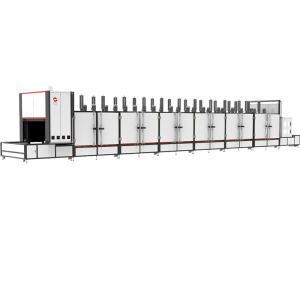

Mesh type IR conveyor tunnel oven

PCB, BGA, FPC, COF, Display, Touch Panel, Back Light, Solar Cell, Smart Card, Optical Film, Battery ,Garment and Semiconductor industries.

1,High quality heating system with anti-attenuation system for heating tube energy

2,Use high-speed circulating fan, equipped with patented air transport system

3,Multi-stage independent control bellows, each stage can be set to different temperatures.

4,The unique cold air circuit in the cooling section can reduce the temperature to room temperature when the board is ejected to ensure that the subsequent process can be carried out

5,There is a maintenance door design, which is convenient for future cleaning and maintenance.

6,Imported Teflon mesh belt is used for conveying, the mesh belt is wear-resistant and runs smoothly

7,Energy-saving mode: energy-saving control mode with automatic heating/off heating

8,With over-temperature indication and alarm function

9,Imported high temperature insulation cotton,completely separate the temperature inside and outside the oven

PLC: MITSUBISHI

Motor: TaiWan

Solid state: AUTONICS

Touch screen: weinview

Heating tube: GER

Thermostat: RKC

Processing size: Plates above 350mm

Board thickness range: 0.02-4.0mm

Temperature uniformity: ±5℃

Conveying method: Teflon mesh belt conveyor

Conveying width: the conveying width can be customized according to product size requirements

Baking method: high-speed circulating hot air + infrared drying

Temperature range: normal temperature -220℃

Exhaust air volume: 6-8m/s

Networking signal: Ethernet port docking