Drying oven series

-

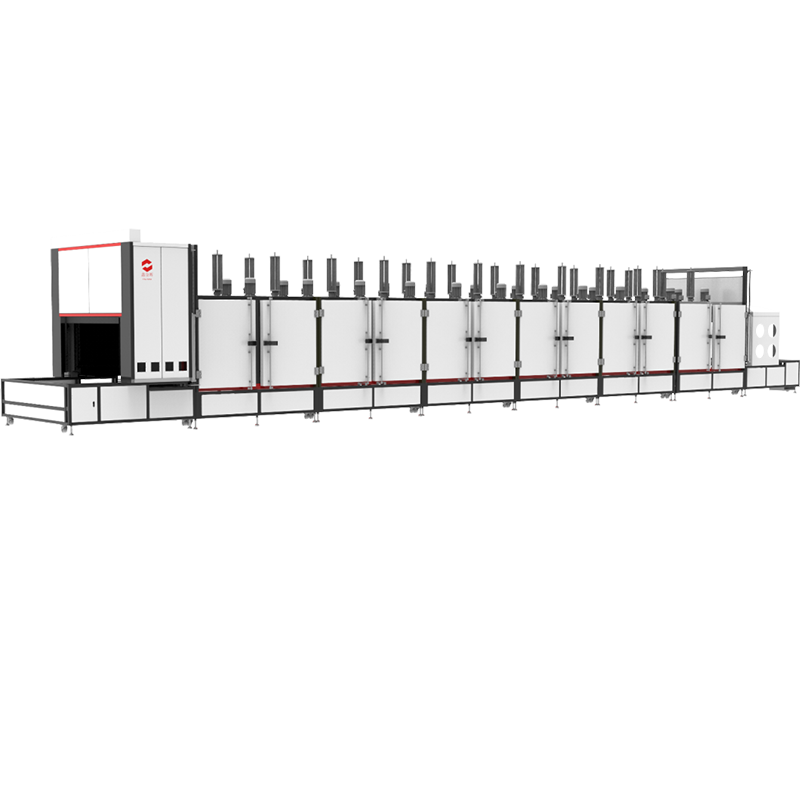

Frame type convery tunnel oven

PCB, BGA, FPC, COF, Display, Touch Panel, Back Light, Solar Cell, Smart Card, Optical Film, Battery and Semiconductor industries.

-

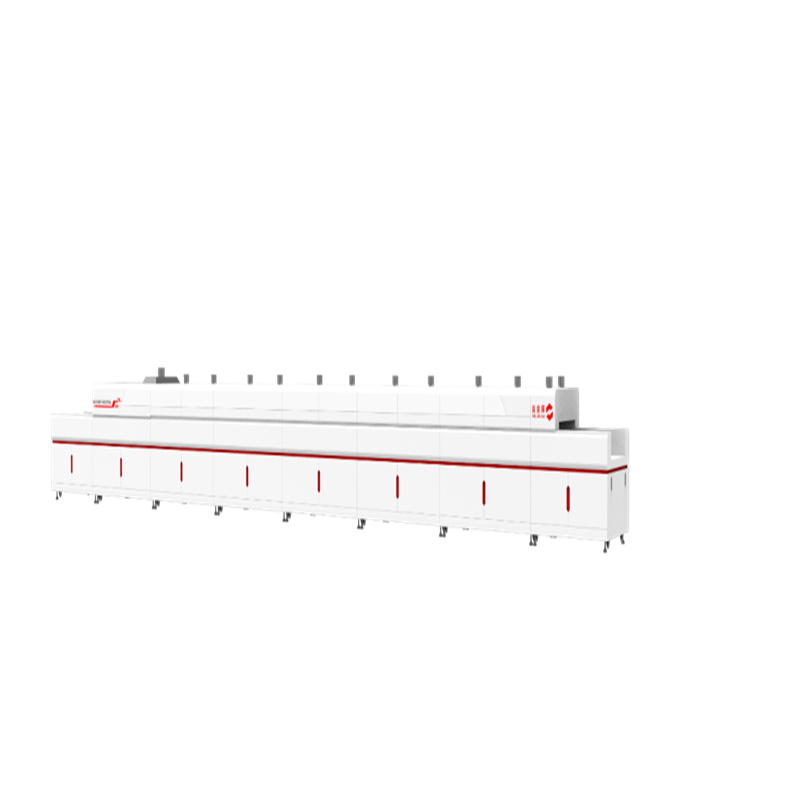

U Type IR Tunnel Oven/drying oven

Product Description

Industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed

travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is composed of feeding section, drying zone matching patented energy-saving generating system, air conveying system, heat preservation system, and unloading section. It adopts imported patented U-shaped conveying design, stable operation and good energy-saving effect. Suitable for pre-bake/post-bake circuit boards. -

Double-Tunnel Page Turning Conveyor Oven

Product Description

Industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed

travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is composed of automatic diverter feeding, drying zone matching patented energy-saving heating system, air conveying system, heat preservation system, and automatic converging machine unloading composition. It adopts unique plate frame design, stable operation and good energy-saving effect. It is suitable for back of circuit boards bake. -

Overhang tunnel drying oven/// hanging type conveyor oven

Product Description

industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed

travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is composed of automatic feeding by a manipulator, the drying area is matched with a patented energy-saving heating system, an air conveying system, a heat preservation system, and an automatic feeding by the manipulator. Using unique patented suspension clamps, stable operation and good energy-saving effect. Suitable for pre-bake/post-bake circuit boards. -

Double -Door Vertical Hot Air Oven

Product Description

The drying area of the whole machine is matched with patented energy-saving heat system, wind system and heat preservation system. Good energy saving effect. Suitable for pre-bake/post-bake circuit boards. -

Independent double door vertical drying oven

Product Description

The drying area of the whole machine is matched with a patented energy-saving generating system, air conveying system, and thermal insulation system. Good energy saving effect. Suitable for pre-bake/post-bake circuit boards. -

Mesh type IR conveyor tunnel oven

Product Description

Industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed

travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is composed of feeding section, drying zone matching patented energy-saving generating system, air conveying system, heat preservation system, and unloading section. Adopting imported Teflon mesh belt conveyor design, stable operation and good energy-saving effect. Suitable for pre-roasting circuit boards. -

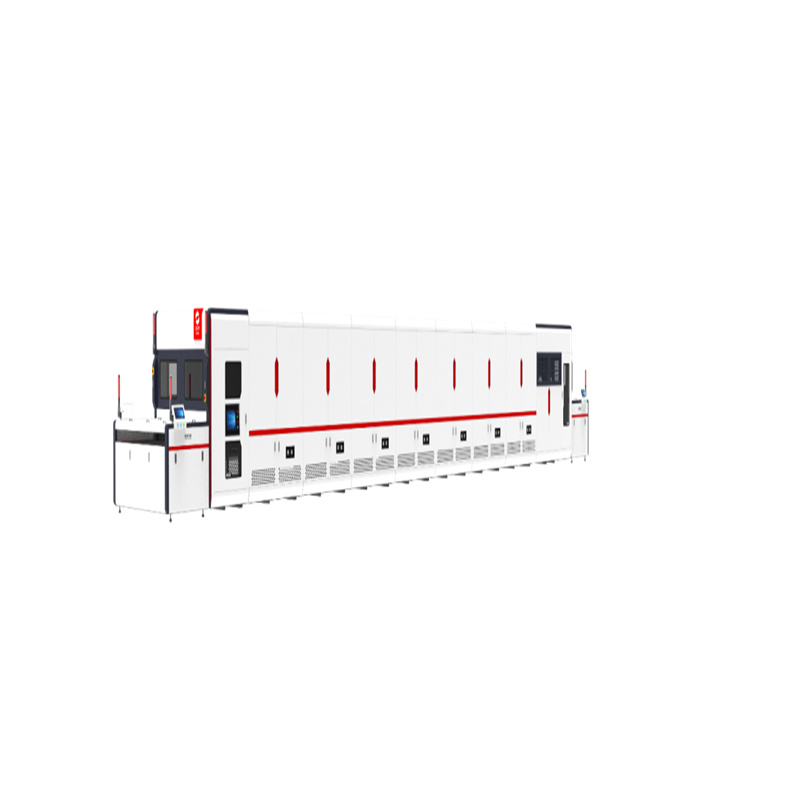

Roller type conveyor tunnel drying oven

Product Description

Industry conveyorised hot air tunnel ovens contain multiple individually electric heated zones, which can be individually controlled for temperature. For example ,PCBs being processed

travel through the oven and through each zone at a controlled rate with reel rolling transmission. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is composed of feeding section, drying zone matching patented energy-saving generating system, air conveying system, heat preservation system, and unloading section. It adopts imported patented roller conveying design, stable operation and good energy-saving effect. Suitable for pre-bake/post-bake circuit boards. -

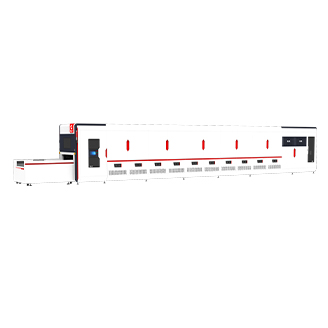

Encapsulated tunnel conveyor drying oven

Product Description

Industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature.Packaging material being processed travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the Packaging material being processed at the time.

The whole machine is composed of feeding section, drying zone matching patented energy-saving generating system, air conveying system temperature system, and unloading section. Adopting a unique metal stall conveying design, stable operation and good energy-saving effect. Suitable for pre-bake/post-bake package substrates. -

Side Clip Conveyor Tunnel Oven

Product Description

Industry conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed

travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time

and temperature profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

The whole machine is loaded by an automatic positioning platform, and the drying area is matched with a patented energy-saving heating system, an air transport system, a heat preservation system, and automatic feeding. It adopts a unique patented side-holding clip, stable operation and good energy-saving effect. It is suitable for pre-baking circuit boards. /After roasting.