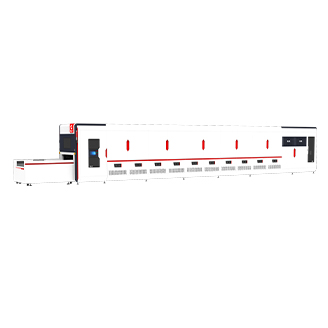

Side Clip Conveyor Tunnel Oven

double-sided multi-layer circuit board solder mask pre-curing, plug hole, character baking board and other processes

1,Adopt patent heating system, energy saving 30%

2,Adopt high-speed circulating fan, equipped with patented wind wheel to transport wind

3,Control panel with color man-machine interface, easy to manage the output and the operation of error elimination.

4,Multi-stage modular heating section, each independent furnace unit can be added or shortened in the future, keeping production requirements more flexible.

5,The unique cold air circuit in the cooling section can reduce the temperature to room temperature when the board is ejected to ensure that the subsequent process can be carried out

6,There is a maintenance door design, which is convenient for future cleaning and maintenance.

7,Adopt patented side clamp, stable and not easy to fall off

8,Energy-saving mode: energy-saving control mode with automatic heating/off heating

9,With 2 sets of over-temperature indication and alarm function

PLC: MITSUBISHIMotor: TaiWan

Solid state: AUTONICS

Touch screen: weinview

Communication: MITSUBISHI

Thermostat: RKC

Maximum processing size: 630 mm×730mm

Minimum processing size: 350mm×400mm

Board thickness range: 0.8-4.0mm

Temperature uniformity: ±2℃

Suspension step: 25.4mm/31.75mm optional

Baking method: high-speed circulating hot air

Temperature range: normal temperature -180℃

Exhaust air volume: 6-8m/s

Networking signal: Ethernet port docking