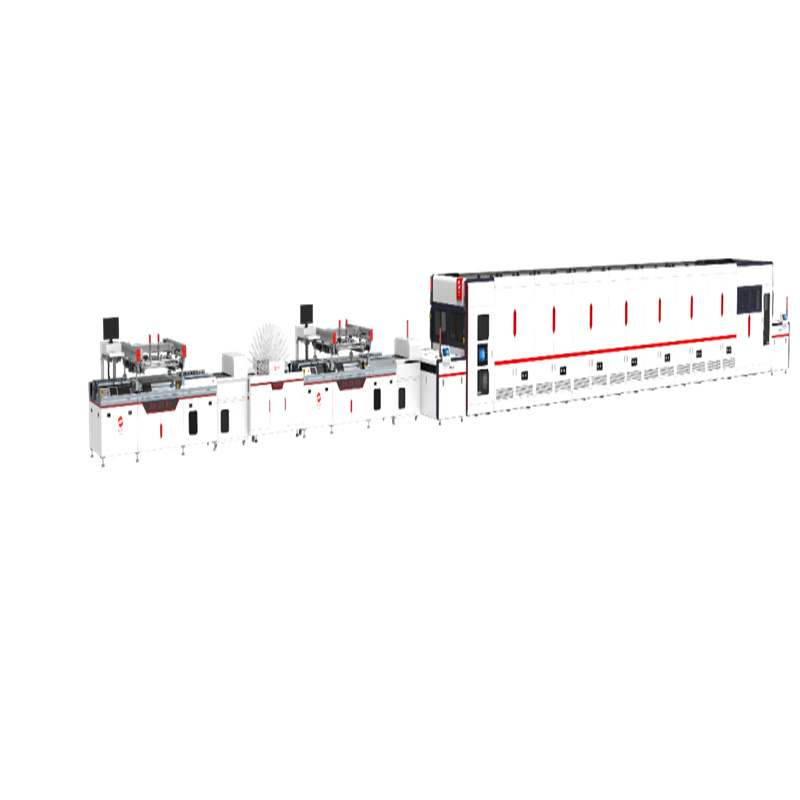

Fully Automatic PCB Legends Screen Printing Line

1,The CCD visual alignment system uses an industrial computer + Windows version of the high-level program to drive the three-axis servo alignment system, which is fast and accurate. The operation interface adopts color LCD screen + wireless mouse.The operation is simple, it only takes 3-5 minutes to switch different panel.

2,The printing section adopts a stable top-level four-column screen printing head, equipped with a variety of uniquely designed precision movement and adjustment mechanisms, running smoothly and quietly, and positioning accurately:

3,Realize [digitalization], [parameterization] and [intelligence],The production capacity reaches 6-8pnl / min

4,Matching cold light source UV machine,fast curing!

5,matching the sun sharp flipping machine,Circuit board temporary storage, cooling, position turning over.

6,The design is based on the concept of "automatic connection operation", and with the horizontal conveyors in the front and rear sections, reduce the cost of the manpower and the production capacity can be increased.

PLC: Mitsubishi

Guide rail: THK

Cylinder: AIRTAC

Communication: Mitsubishi

Touch screen: weinview

Synchronous belt: Megadyne

Bearing: NSK

Ball screw: TBI

Processing size

Maximum: 630mm * 730mm

Minimum: 350mm * 400mm

processing thickness

Maximum thickness: 4.0mm

Thinnest: 0.8mm

production efficiency

Maximum: 8pnl / min

Minimum: 6pnl / min