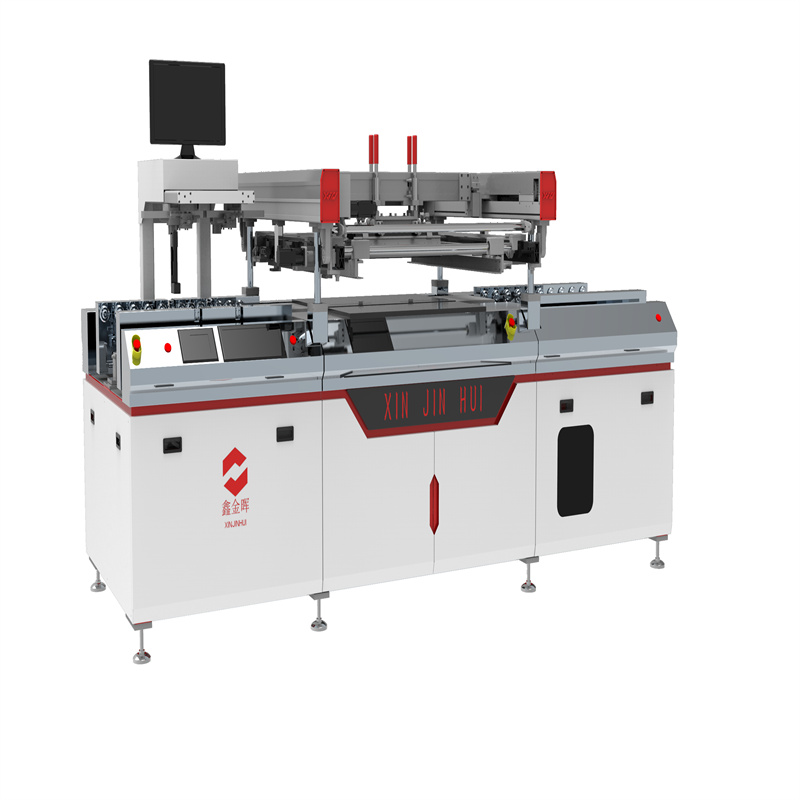

Automatic smart silk screen printing machine

PCB solder mask printer,pcb legends printer,glass silk screen printing,solar silk screen printing,pvc,movbile cover and so on

The whole machine is composed of a fully intelligent CCD system alignment section, printing section and material return section, with the left and right shuttle table in the middle to move the printed parts in series. Suitable for solder mask/character ink printing.

1,The feed positioning adopts a full-servo automatic plate matching system, and the positioning accuracy reaches the um level.

2,Servo motor drives printing and pneumatic off screen to realize synchronous off screen function and effectively prevent screen sticking. The servo motor drives the printing piece to move quickly and smoothly to ensure the accurate positioning of the printing piece.

3,Servo motor and precision guide rail guide ensure accurate positioning and longer service life. The vertical horizontal lifting structure of the printing frame ensures that the pressure of the scraper is balanced.

4,smart interface touch operation, easy to set, and automatic fault detection and troubleshooting display. The printing pressure and screen plate can be adjusted conveniently and accurately, and the angle of the scraper can be adjusted at will.

5,CCD image automatic alignment system, combined with left and right running platforms, enables faster operation and high alignment accuracy. The multi value processing of the image system is not limited by any graphics, and any graphics can be used as a target.

6, Discharge section

The discharge section is equipped with discharge conveying rollers to take the treadmill and bring it into the base plate, and bring it back to the conveyor.

The above design is based on the concept of "intelligent connection operation", and with the horizontal conveyors in the front and rear sections, the input manpower can be greatly reduced and the production capacity can be increased.

PLC: Mitsubishi

Guide rail: THK

Cylinder: AIRTAC

Communication: Mitsubishi

Touch screen: weinview

Synchronous belt:MEGADYNE

Bearing: NSK

Ball screw: TBI

Maximum processing size: 630 mm×730mm

CCD alignment lens: 4

Minimum processing size: 350mm

×400mm

CCD resolution: 130

Board thickness range: 0.8

-4.0mm

CCD resolution: 12um

Printing speed: 30~300 mm/sec adjustable

CCD working range: 300-720mm

Maximum screen frame size: 1200×1100mm

CCD effective field of view: 12*15mm

Minimum screen frame size: 800×800mm

CCD imaging target size: 1-3mm

The smallest plug hole diameter:

≤ 0.20mm

Available types of CCD targets: unlimited

Table top level accuracy: ±0.1mm/m2

CCD imaging accuracy: 0.01mm

Plug hole accuracy: ±0.02mm

CCD imaging depth of field: 0-2mm

8-point clamping center positioning and CCD automatic positioning

Squeegee pressure uniformity: ≤5kgf

Covering/scraping angle:

±15°

Printing distance: 0~10 mm

Scratch stroke: servo 0~900 mm adjustable

Clearance from the board: 0~10mm

Plug hole pad design: divided into three pieces

Fine adjustment of screen frame: X, Y, θ±5mm

Equipment power: 5.6/ KWH