Today, as electronic products become increasingly popular, circuit boards serve as carriers for electronic components and wires, and their manufacturing process and quality directly affect the performance and life of the entire electronic product. In the production process of circuit boards, PCB circuit board solder mask screen printing is an indispensable link. The process principles, application scenarios and innovations of circuit board character screen printing and PCB solder mask printing will be discussed in depth, and you will be able to appreciate the charm of PCB screen printing technology.

1. Basic concepts of circuit board solder mask screen printing

Circuit board solder mask screen printing is a selective printing process that uses a screen and a scraper to print ink on a flat printed circuit board. The main purpose of this process is to protect the copper surface on the circuit board, prevent the “bridging” phenomenon between the two wires caused by the disordered flow of solder during the welding process, and ensure the quality of the electrical installation.

2. Application scenarios of circuit board solder mask screen printing

Circuit board solder mask screen printing is widely used in various fields, such as automotive electronics, communication equipment, medical equipment, etc. Through solder mask screen printing technology, specific marks, names, symbols, production dates, company logos, etc. can be printed on the circuit board to improve the recognition and aesthetics of the circuit board.

3. Innovations in circuit board solder mask screen printing

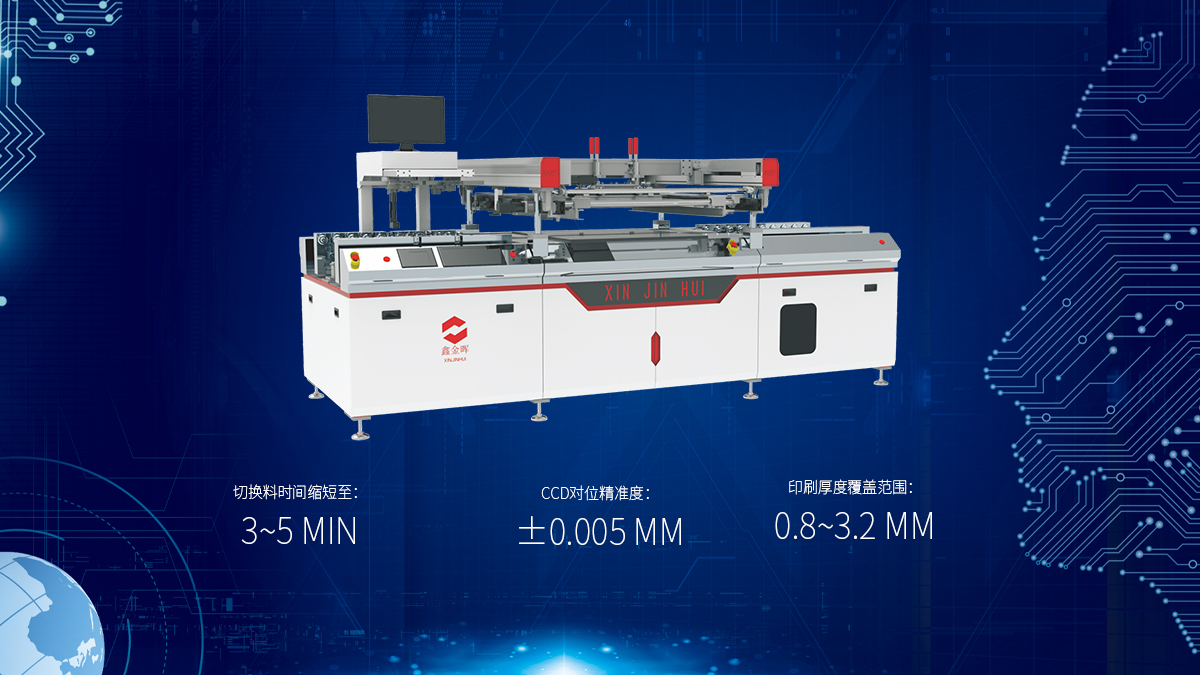

With the rapid development of the electronics industry, traditional circuit board solder mask screen printing technology has been unable to meet market demand. To this end, many researchers and companies are constantly exploring and innovating, and are committed to improving printing quality and efficiency. Take the series developed by Xin Jinhui, which is intelligent and fully automatic, as an example. It not only uses a CCD intelligent alignment system, but also develops a self-developed machine vision algorithm for automatic positioning, compensation and adjustment. It is combined with a full servo plate alignment system for feeding materials without the need for handwheel adjustment. It is efficient and convenient, and switching The material time is shortened to 3~5 minutes, and the daily production is increased by 1000~2000 pieces; scientific and reasonable mechanical structure ratio, mechanical self-locking function, four-column power lifting design, and 20 years of R&D system quality control make the machine run accurately, efficiently and stably. Reliable, based on intelligent automation and humanized design, it reduces the threshold and dependence on manual technology, saves labor costs, reduces costs, increases efficiency and improves quality, and greatly improves the comprehensive benefits of the PCB screen printing process.

4. Successful cases of circuit board solder mask screen printing

In recent years, circuit board solder mask screen printing technology has continued to make breakthroughs, and many successful cases have made people deeply aware of the value of this technology. Xin Jinhui is deeply involved in the PCB circuit board industry, focusing on the R&D and innovation of circuit board hole plugging, silk screen printing and drying technology, and opening up related processes to solve the difficulties and pain points of multi-process intelligent manufacturing for PCB customers. Based on PCB thick plate, thin plate, extra large version, miscellaneous Material No. has launched a fully automatic intelligent plug-hole solder mask drying production line to help customers save 5 to 7 laborers. It is widely compatible with the production of 0.8mm to 6.0mm circuit boards. It has ultra-high utilization and is empowered by digital, parametric, and intelligent technologies. Combined with the world’s top electrical hardware configuration, multiple inventions and utility model technology patent blessings, the entire line consumes only 36 kilowatt hours per hour, saving 30% of energy. The entire line operates with high quality, high efficiency, low energy consumption and stable operation, and has been recognized by many listed PCB companies. It is favored, recognized and widely put into production and used all over the country. It has received enthusiastic response and is highly praised.

5. Conclusion

As an efficient and beautiful circuit board manufacturing process, circuit board solder mask screen printing has been widely used in various fields. With the rapid innovation of electronic product technology, the PCB circuit board process is also constantly innovating and improving, providing strong support for the development of the electronics industry. The level of PCB screen printing technology will seriously affect the quality results. With the miniaturization of electronic products, a small error may cause huge losses to manufacturers. Therefore, you must choose professional equipment manufacturers and excellent machinery and equipment. Since 2003, Xinjinhui has successively established Shenzhen Xinjinhui Energy Saving Technology Co., Ltd., Dongguan Pengli Energy Saving Equipment Co., Ltd., and Jiangxi Xinjinhui Intelligent Technology Co., Ltd. It has always focused on the invention and creation of core technologies, fully interpreting the expertise and understanding of the industry. The basic principle of professionalism in the industry. In the past 20 years, it has made outstanding contributions to more than 3,000 PCB circuit board manufacturing companies in realizing intelligent automation, energy saving, cost reduction and efficiency improvement. It is a fully automatic screen printing machine, pressure plugging machine and oven for PCB circuit board companies. , the best choice for fully automatic multi-process production lines.

Post time: Jan-22-2024