The oven is a continuous baking and drying equipment, commonly used in food, pharmaceuticals, acrylic molds, silicone rubber, metal products, hardware workpieces, printing, electronic circuit boards, LED, LCD, instrumentation, touch screens, etc. that require large quantities. Large-scale drying industry, so the tunnel oven is also called the tunnel oven drying production line. Next, the editor will introduce to you the function and working principle of the tunnel oven as well as the types and differences of tunnel ovens.

1. The function of tunnel furnace

The function of the tunnel oven is mainly to bake all kinds of items that need to be baked and dried. With the energy-saving characteristics of the tunnel oven, through the automated and continuous baking mode, it can achieve effective, energy-saving, low-cost and high-profit baking production operations. Secondly, for different The baking process needs to achieve the stability of physical form and complete chemical reactions, such as: drying of internal and external moisture to avoid affecting the quality of subsequent processes, improving quality and stability through uniform baking, eliminating stress, and improving the quality of items. Plasticity and mechanical properties, prevention of deformation and cracking, curing of surface coating protection processes, etc., to achieve shaping, heat shrinkage, aging, as well as baking in the food industry, pharmaceutical sterilization and dehydration, etc.

2. Working principle of tunnel furnace

The working principle of the tunnel furnace is not complicated. We will introduce it to you along the working process of the tunnel furnace. After the equipment is started, the tunnel furnace heating system will heat up to the preset baking operation temperature. During this period, the wind turbine will The wind blows into the air duct and into the tunnel furnace, forming a high-speed circulating hot air, which is evenly blown to every corner of the tunnel furnace. The conveying system will transport the materials according to the baking rhythm. During the baking operation, various Settings, automatic temperature control, speed change, etc. ensure the completion of baking goals and achieve energy-saving and efficient production.

3. Types and differences of tunnel furnaces

Tunnel drying equipment plays different roles in different production processes in different industries and fields, and has different requirements for the performance parameters and structural design of tunnel furnaces. The following is a differentiated introduction to tunnel furnaces based on different dimensions:

1. According to heating energy:

▶ Flame tunnel furnace: gas tunnel furnace, oil tunnel furnace, coal tunnel furnace

▶ Electric tunnel furnace: electric heating tube heating-electric tunnel furnace, infrared heating-far infrared tunnel furnace, microwave heating-microwave tunnel furnace

▶Steam tunnel furnace: a steam tunnel furnace that electrically heats water and boils water to form steam

2. According to heating temperature:

▶ Low temperature tunnel furnace: 0~150℃

▶ Medium temperature tunnel furnace: 150~300℃

▶ High temperature tunnel furnace: 300~500℃

▶Ultra-high temperature tunnel furnace: above 500℃

3. According to the transportation method:

▶Suspended tunnel furnace

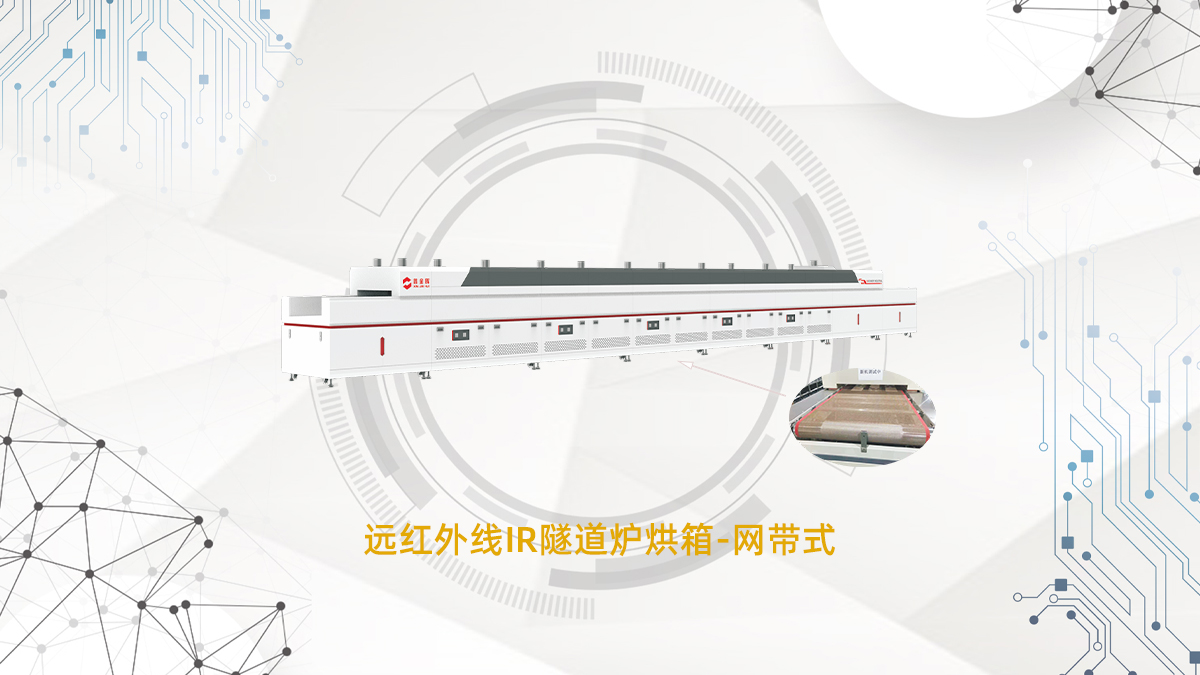

▶ Mesh belt tunnel furnace

▶ Side clamp tunnel furnace

▶ Side-hugging tunnel furnace

▶ Flip-type tunnel furnace

4. According to the number of channels:

▶Single channel tunnel furnace

▶Double channel tunnel furnace

▶Multi-channel tunnel furnace

5. According to industry technology:

▶ Food Tunnel Oven

▶ Tunnel furnace drying line for clean room

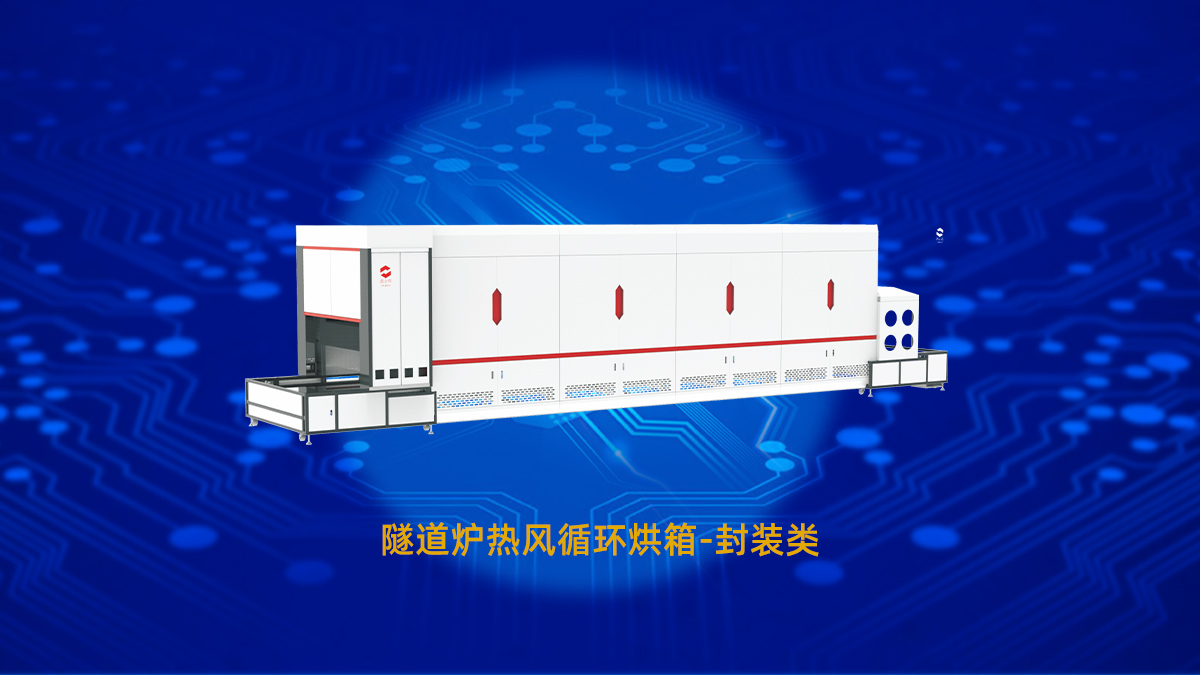

▶ Hot air tunnel oven drying line

▶ IR far infrared absorption

▶ Circuit board solder mask pre-baking/text post-baking tunnel oven

4. Introduction and summary of tunnel furnace

The tunnel furnace is a tunnel-type oven equipment. Due to the large differences in the process index requirements of different industries, it is difficult to form a direct comparison in terms of performance parameters and cost prices. Therefore, it is recommended that everyone choose a dedicated tunnel furnace. In order to better play the role of the tunnel oven, secondly, look for a professional tunnel oven manufacturer for professional customization. As we all know, the baking and drying process is very power-consuming. Even though the tunnel oven is a more energy-saving type, each brand There are differences in energy-saving benefits. If you need to bake for a long time and consume a lot of energy, it is recommended to purchase an energy-saving tunnel oven. It can save a lot of electricity costs for the company. At the same time, the quality and benefits of baking are also extremely ideal. Jiangxi Xinjinhui Intelligent is especially recommended. Technology Co., Ltd. is a top-ranked and powerful brand in the ranking of energy-saving tunnel furnace manufacturers in China and even the world, and it is a domestic brand with higher cost performance.

▶ Glass silk screen printing tunnel oven drying line

▶LED photoelectric packaging curing tunnel furnace

▶ Segmented baking tunnel oven

▶ Frame type multi-layer tunnel furnace

▶ Foam material tunnel furnace

Post time: Jan-13-2024