As an indispensable oven equipment for the baking and drying production process, the dryer production line consumes huge amounts of electricity and electricity costs every day. In the context of the increasingly harsh global environment and dual-carbon strategy, how to reduce factory energy consumption and save energy? , has become the direction of efforts to enhance the company’s comprehensive advantages and competitiveness. Therefore, it is particularly important to choose ideal and cost-effective equipment. This issue brings you a dryer production line purchasing guide and teaches you three steps to choose the right oven equipment.

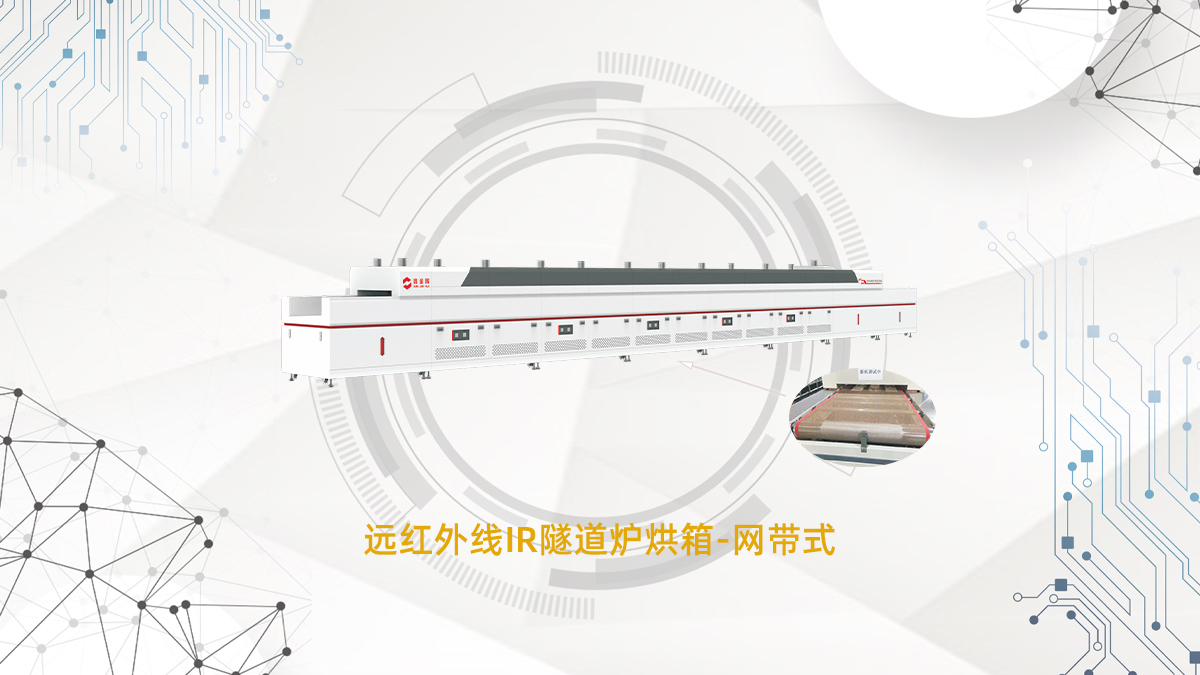

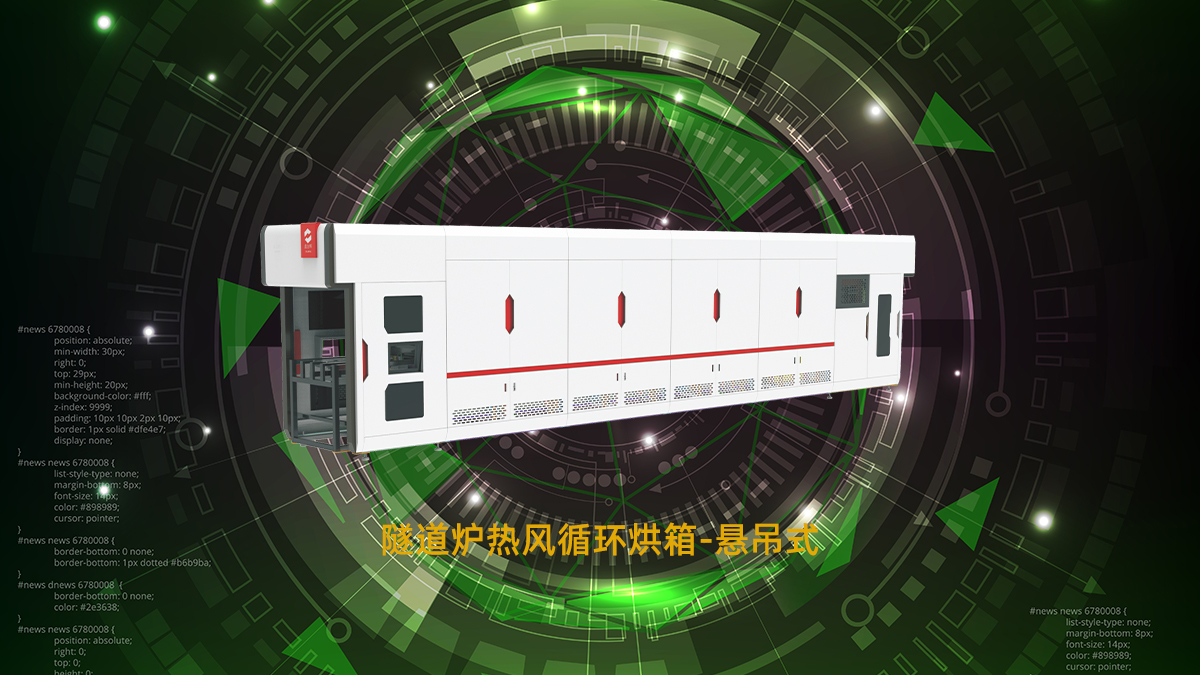

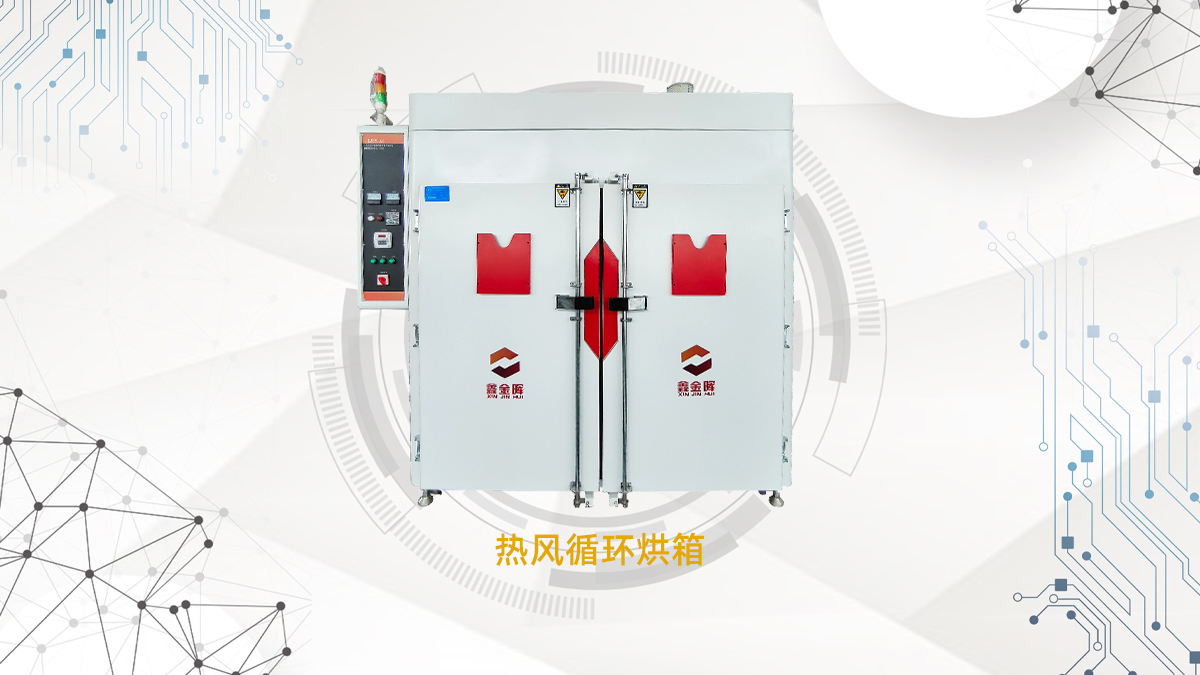

Xin Jinhui’s following three-step purchasing guide for dryer production lines will help you master the core purchasing points of far-infrared, tunnel drying box equipment, vertical, baking and drying production lines and other drying equipment, so as to achieve Businesses can save energy and money by buying the ideal drying equipment.

The first step, how to identify whether the dryer production line equipment saves energy: focus on energy consumption, not power

Many people have a misunderstanding that the higher the power of the dryer equipment, the more electricity it consumes. In fact, this is not necessarily the case. This is related to the drying mode of the oven equipment and the drying process of the manufacturer, because not all drying production lines use The peak power is used for drying, and the operation process is affected by the core modules of energy consumption such as the heating system, temperature control system, and insulation system. The final power consumption cannot be calculated directly in terms of power. Therefore, when purchasing tunnel furnaces, hot air circulation ovens, and dryers, When baking equipment such as production lines, you must pay attention to the energy consumption level. Even if the difference is 1%, it will be a huge expense if the base is large.

The second step, how to judge the efficiency level of dryer oven equipment: focus on production efficiency, not production capacity

Comparison is only valuable under the same environment and production conditions. The effectiveness of dryer production line equipment cannot be judged by a single production capacity value. Assume that a PCB circuit board hot air circulation oven can bake 100 PCBs in one hour. board, the power consumption is 40 degrees, which is equivalent to 0.4 kilowatt-hours of electricity per piece; but another PCB hot air circulation oven can only bake 50 pieces in an hour, but the power consumption is only 10 degrees, which is 0.2 kilowatt-hours per piece. kWh, obviously the latter has lower production capacity but better production efficiency.

Of course, sometimes output is a rigid indicator for purchase. At this time, we can choose non-standard customization. It should be noted that the technical difficulties of drying equipment such as far-infrared tunnel furnaces, tunnel-type hot air circulation ovens, and baking production lines lie in heating, insulation, and control. Temperature, temperature uniformity, safety, etc. are relatively simple compared to the size and output of the chassis equipment. Therefore, when we define the level of efficiency, it is more valuable to calculate the production efficiency of the equipment.

The third step, how to judge the cost performance of dryer and oven equipment: focus on value, not price

The dryer production line needs to run for a long time, coupled with high-temperature baking conditions. Based on the properties of different materials, pollutants such as waste water, waste gas, condensation, and organic residues may appear. In addition to requiring scientific maintenance, the machine itself Materials, mechanical structure design, electronic component quality and other aspects have put forward higher requirements for long-term stability, baking quality, equipment life, parts replacement, maintenance costs, etc., so we cannot blindly compete. Price, but value, is the only way to choose the ideal equipment based on a comprehensive evaluation of cost performance.

The above is an inventory of 3 steps on how to choose dryer production line equipment. I believe it can help you avoid detours and avoid pitfalls, and truly save energy and money. In addition to the definition of the equipment itself, in the selection of drying equipment manufacturers You must also choose carefully. If you want to achieve both energy-saving technology, baking quality, comprehensive efficiency, stability and lifespan, you must choose a strong or oven manufacturer with independent R&D and production capabilities, years of technology accumulation, and safety. And after-sales are guaranteed. For example, Xinjinhui brand tunnel ovens, tunnel ovens, vertical hot air circulation ovens, and baking production lines have been in the market for 20 years and inspected by more than 3,000 corporate customers. Many products have been certified by the Industry Contribution Award. Always at the forefront of the times, many customers even have no after-sales record after 10 years of use. It is stable and reliable and is the industry benchmark for far-infrared tunnel furnaces and hot air circulation oven equipment. It provides professional reform plans and equipment based on the customer’s baking on-site process conditions. , help reduce costs and increase efficiency, and drive customers’ profits and benefits to double.

For more technical principles, purchase suggestions, operation and maintenance of tunnel furnaces, hot air circulation ovens, and dryer production line equipment, please pay attention to Xinjinhui PCB Equipment Network, which will answer your baking process problems online and provide free technical solutions. , quick quotation, and has built a large exhibition hall and R&D and manufacturing base to provide on-site inspections. Welcome to call or leave a message for consultation.

Post time: Apr-03-2024