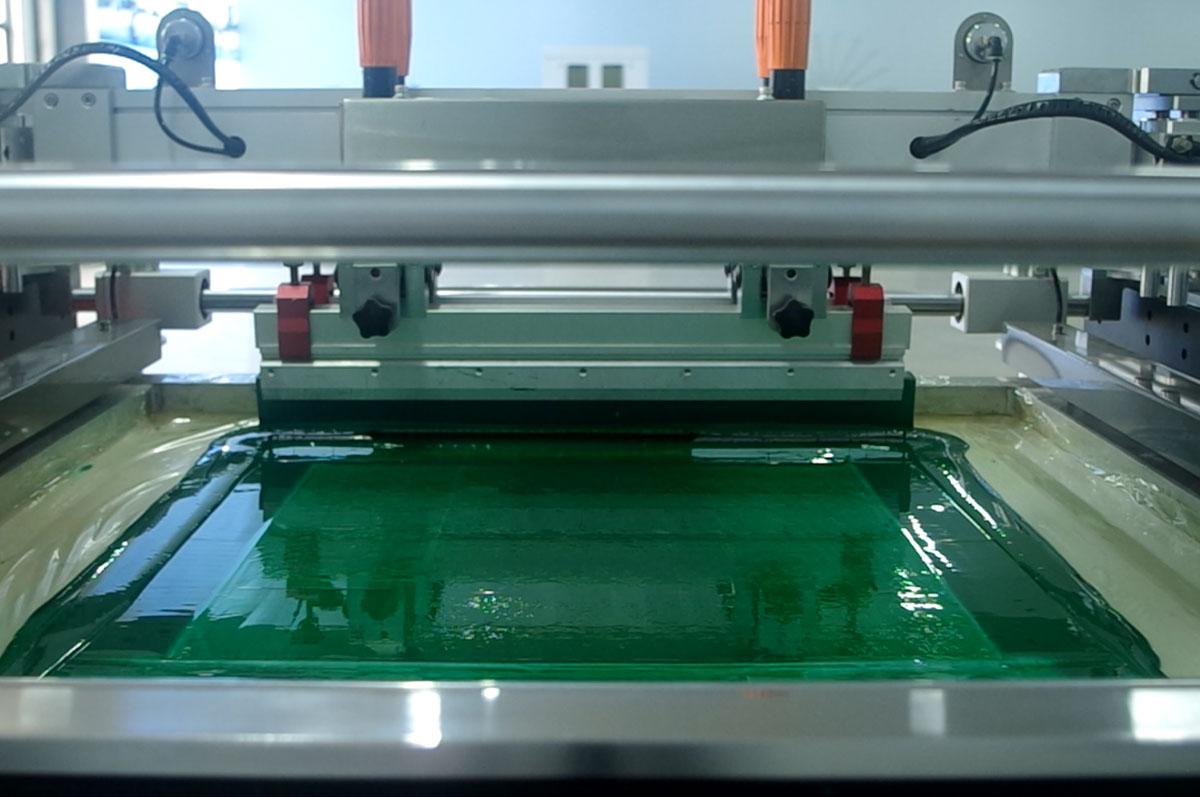

The quality and performance of PCB circuit boards play a decisive role in the entire electronic product industry. The same solder mask process is also an important line of defense for circuit board quality. The quality of PCB manufacturers’ solder mask screen printing technology and equipment will have a significant impact on the quality of PCB boards. It has a profound impact on production efficiency and even the comprehensive benefits of the factory. This article uses 20 years of experience in PCB circuit board text/equipment technology to introduce to you 10 tips on the process operation and maintenance of PCB circuit board solder mask screen printing machines!

1. Tip 1

There is a lot of knowledge in the selection of screen mesh. For different printing needs, you need to use the appropriate screen mesh to get the expected printing effect. Although the smaller the mesh, the more ideal the printed details will be, but it does not mean that the smaller the mesh, the better. The better, it mainly depends on the equipment accuracy and printing requirements of the PCB board solder mask screen printing machine.

2. Tip 2

The tension of the screen is usually moderate, because when the tension is small, the screen will be stressed during the process and become loose, resulting in insufficient printing clarity. On the contrary, if the tension is too high, the screen may be directly broken and damaged. , so the tension adjustment of the screen also tests the experience of a screen printer.

3. Tip 3

The screen should be cleaned and replaced. After long-term screen printing, the ink will remain and block the screen, resulting in defective products. Therefore, inspection and debugging must be carried out before and after every production to avoid affecting the printing quality and causing loss and waste.

4. Tip 4

The printing film must be clear and clean, and must be checked for defects or scratches. Before use, photosensitive adhesive must be applied where necessary to effectively guarantee the clarity of the image.

5. Tip 5

The setting of printing parameters will directly affect the printing effect, so pre-production machine testing is extremely important. The printing pressure, time and speed need to be adjusted to the parameters suitable for current product printing, thereby effectively improving the quality, efficiency and stability of printing. Try to avoid waste board rework and other phenomena as much as possible. Since there are many PCB models, it is a huge waste of time to change the production and adjust the machine every time. It also relies on the experience and technology of the solder mask screen printer, so the intelligent level of the solder mask screen printer , the speed of model change and production change is very important, which greatly affects the overall production efficiency.

6. Tip 6

Ink is one of the key factors in the quality of solder mask screen printing. Therefore, the ink must be selected from a dedicated solder mask to ensure the screen printing effect. Secondly, the color and year of the ink must be selected according to the solder mask requirements.

7. Tip 7

In order to prevent problems such as ink solidification, the ink must be stirred regularly to keep it in a stable state, thereby avoiding mesh clogging during the printing process.

8. Tip 8

Monitor the temperature and humidity of the environment. Because the temperature and humidity have a certain impact on the fluidity and adhesion of the ink, we must master the parameters of the production environment and adjust accordingly to avoid unnecessary effects on the quality of screen printing.

9. Tip 9

Learn from the experience of PCB board solder mask screen printing, summarize the data and methods and techniques, discover the links that affect printing efficiency and quality, and optimize the process flow, thereby bringing benefits to PCB manufacturers.

10. Tips 10

Nothing is better than an omission. We must pay attention to the quality inspection of each production step to avoid big losses due to small oversights. Discover them in time to reduce the impact.

By following the 10 tips introduced by Xin Jinhui above, you will be able to complete the PCB circuit board solder mask screen printing process better and more smoothly, thereby improving production efficiency and product quality, avoiding unnecessary losses and waste, and effectively promoting comprehensive benefits. improvement. I hope that the above introduction can help your company in the operation, use and maintenance of PCB circuit board solder mask screen printing machines and in the production process!

Post time: Mar-06-2024